Manufacturer of flexible tubes for the packaging of cosmetic creams

Manufacturer of flexible tubes for the packaging of cosmetic creams

Are you looking for new plastic or eco-friendly tubes?

Plastic & Eco-friendly tubes

Discover our plastic tubes and eco-responsible tubes.

Our assets

Why trust Ets Bugnon for the manufacture of your tubes?

Customer Focus

Short leadtime

Reactivity

Small batches possible

Quality products

Made in France production

Manufacture of flexible tubes

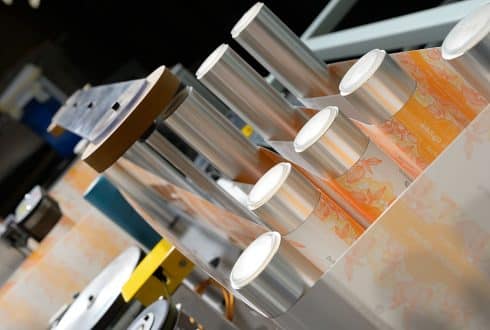

MANUFACTURE OF EXTRUDED AND MULTILAYER PE-EVOH-PE FLEXIBLE PLASTIC TUBES.

Ets Bugnon is a French SME producing flexible tubes for the packaging of cosmetic, pharmaceutical and veterinary products, hygiene and maintenance products, and industrial products.

We are at your disposal to offer you a technical study and personalized advice, in order to design a packaging highlighting your products.

A modern machine park and innovative techniques are a guarantee of quality products. Specialized in small and medium series of flexible plastic tubes, we guarantee a short lead time and reactive exchanges, for the success of your projects.

Geographically located in the heart of the European market, our main customers are based in France, Western Europe and North Africa.

Our fields of application

Cosmetic

Hair gel, cleansing

D.I.Y

Fat, wood paste, coating

Sport/hobbies

Articular gel, relaxing gel, massage gel

Skincare

Scrub, exfoliating, sunscreen, hand / foot cream, lubricant, hair care, moisturizing balm

Cleaning

Laundry detergent, polish wax

Food

Jam

Hygiene

Shaving cream, shower gel, shampooing, toothpaste

Animals

Shampoo, relaxing gel

Vehicle

Base oil

Our news

All the news about the plastic tubes industry.